Introduction

Temperature extremes are among the critical environmental factors affecting electronic device performance. For data storage, particularly solid-state drives, thermal stability directly impacts not only speed and longevity but also data integrity. As SATA SSDs continue to be widely used in consumer, industrial, and enterprise scenarios, the question arises: can they perform reliably in both high and low temperature conditions? This article explores how SATA SSD suppliers ensure stable operation across a wide thermal range.

Operating Temperature Ranges and Standards

Most commercial-grade SATA SSDs are designed to operate within a standard temperature range of 0°C to 70°C. However, industrial-grade models can function reliably from -40°C up to 85°C. SATA SSD suppliers categorize products based on their intended use environment, with stricter thermal tolerance required for industrial automation, transportation, military systems, and outdoor installations. These temperature thresholds are validated through extensive testing to confirm consistent performance across the full specified range.

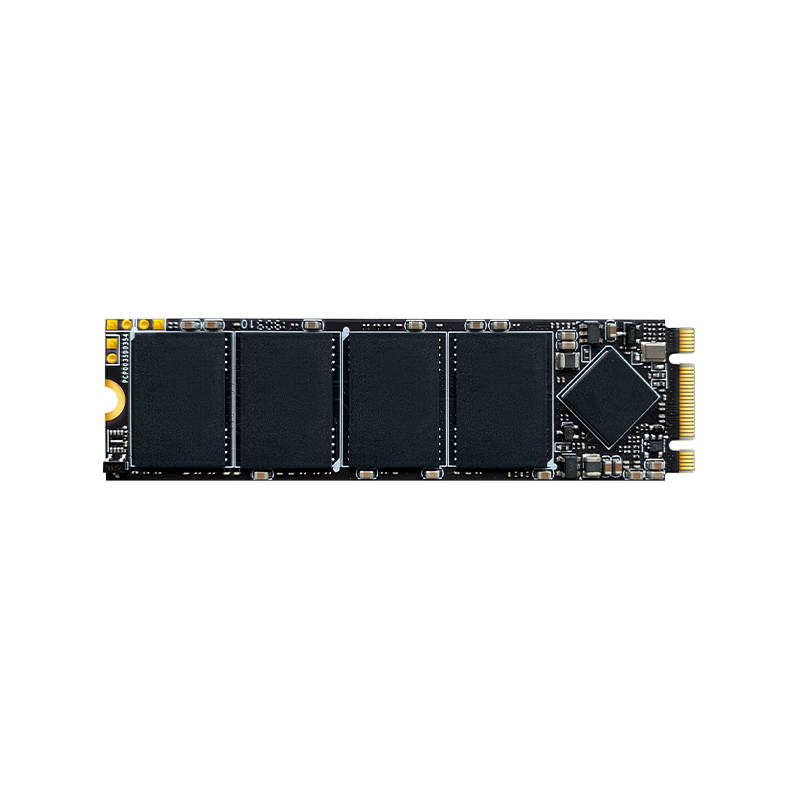

Component Selection for Thermal Endurance

To maintain operational stability in bad conditions, suppliers select components that are specifically rated for wide-temperature performance. NAND flash memory and controller chips must retain their electrical characteristics at both ends of the temperature spectrum. In high-temperature environments, materials must resist thermal degradation, while in low temperatures, they must avoid latency increases or circuit instability. Capacitors, PCB materials, and solder joints are also chosen to maintain conductivity and mechanical integrity under thermal stress.

Thermal Management and Protective Design

Thermal design is a core part of SSD development. Some SATA SSDs include integrated heat spreaders or aluminum enclosures that assist in passive cooling. In applications where airflow is limited, these features help dissipate heat generated by sustained read/write operations. For low-temperature environments, enclosures and insulation may be used to retain heat and prevent condensation. SATA SSD suppliers may also implement firmware-based thermal throttling that adjusts performance to protect components from overheating while maintaining operational continuity.

Environmental Testing and Validation Procedures

Reputable SATA SSD suppliers conduct rigorous environmental testing to ensure performance consistency across bad temperatures. These tests simulate continuous operation in temperature chambers, evaluating data retention, write endurance, error rates, and latency. Shock and vibration tests are also combined with thermal cycles to replicate real-world challenges. The drives are monitored for performance degradation, component failure, and data loss, and only units that meet strict reliability criteria are released to market for critical or industrial applications.

Impact on Performance and Longevity

While SATA SSDs can operate in bad environments, temperature extremes may still affect performance and endurance over time. High temperatures can accelerate NAND cell wear and reduce write endurance, while low temperatures may affect controller response time or increase power consumption. Suppliers compensate for this by optimizing wear-leveling algorithms, error correction protocols, and temperature monitoring systems to improve data reliability even in thermally demanding conditions.

Use Case-Specific Solutions

To meet the needs of specialized industries, SATA SSD suppliers often offer temperature-rated product lines tailored to specific applications. For example, SSDs used in aerospace, mining, or roadside infrastructure are engineered with extended thermal tolerances and reinforced protective features. This level of customization ensures that users in mission-critical sectors can rely on consistent storage performance regardless of environmental challenges.

EN

EN CN

CN ES

ES RU

RU